JOMINY TESTING

The Jominy test (End Quench Test) is a standardized test procedure used to determine the hardenability of steel, and it can be performed using any Vickers micro hardness tester.

- The procedure is described in the following standards: ASTM A255 / ISO 642 / DIN 50191 / BS 4437

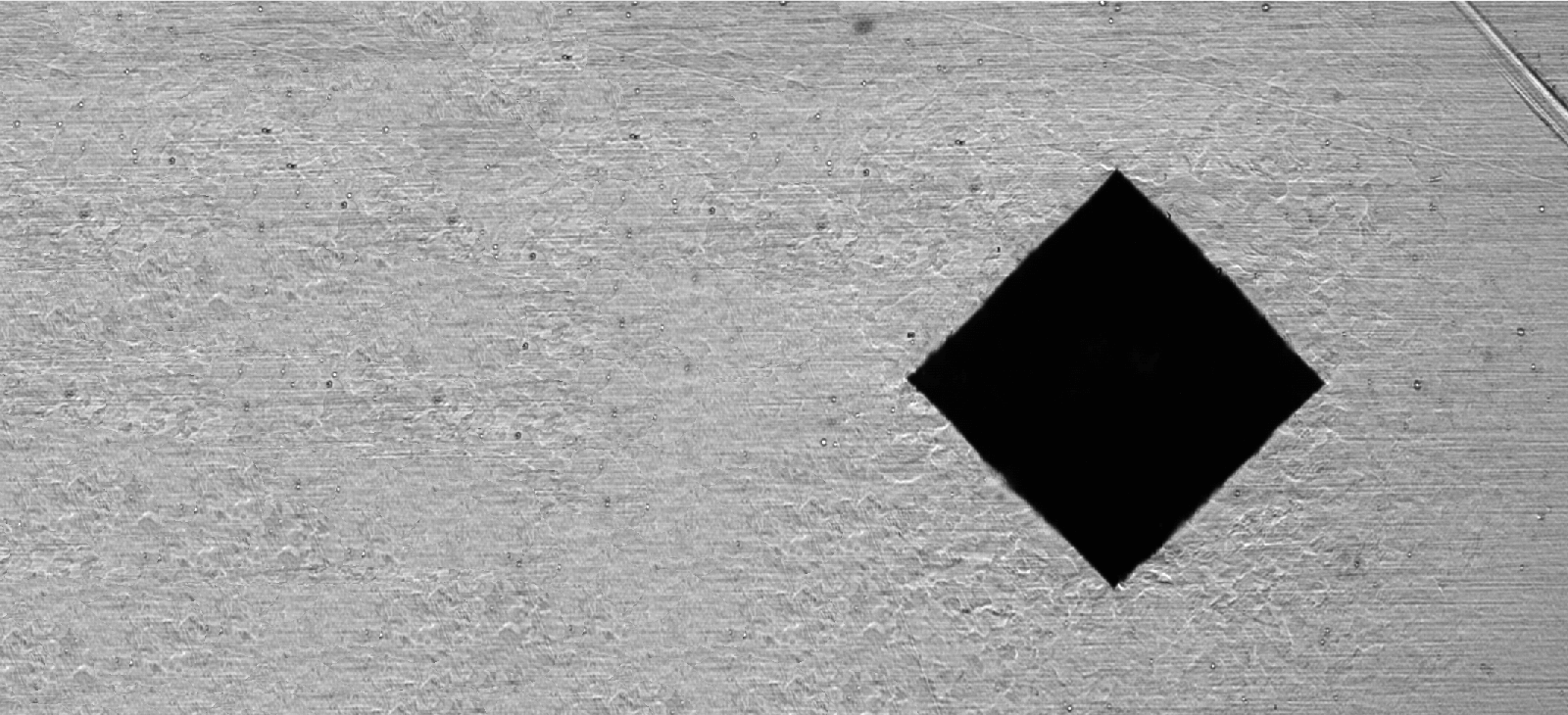

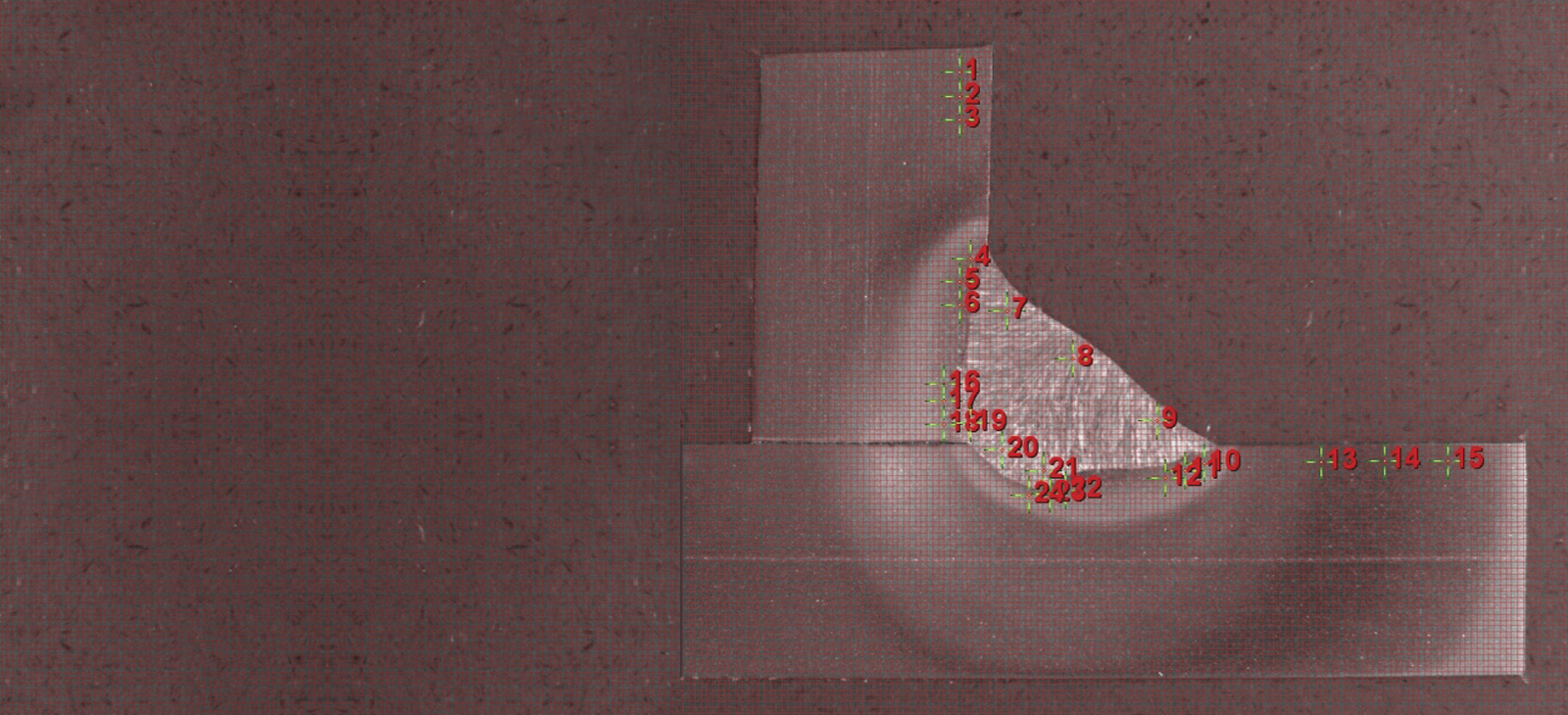

The Jominy test involves heating a cylindrical steel test piece to an austenitizing temperature (~980°–1010°C) and quenching (cooling) from one end, with a controlled and standardized jet of water. After quenching, the hardness is measured at intervals taken from the quenched end. The test method used is either HRC or HV30.

The hardness variation along the test surface is a result of microstructural variation that arises as the cooling rate decreases with the distance from the quenched end. The harder the material at a given distance from the end, the higher the hardenability of the steel.

Both the Vickers and the Rockwell hardness tests are often used for Jominy testing. When selecting which to use, pay attention to the relevant standards, as well as the usual criteria when choosing between different types of hardness test.

Find out more about the Rockwell hardness test