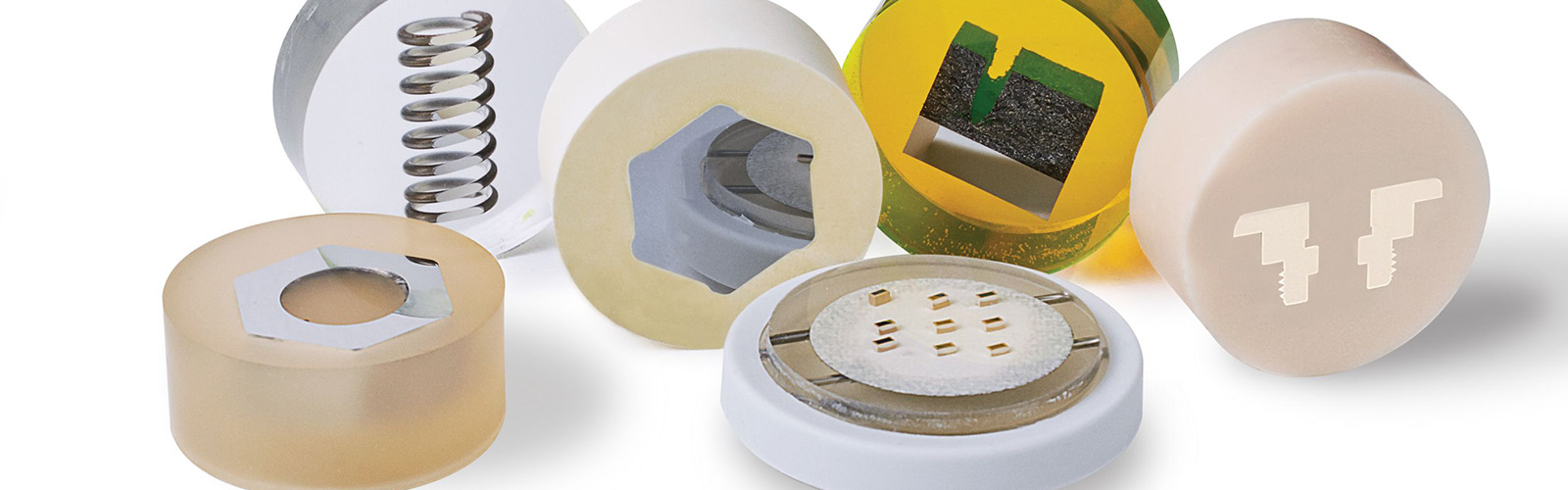

Which epoxy resin is best for your cold mounting process?

For vacuum impregnation and high edge retention

Suitable for mounting all types of materials, epoxy cold mounting resins are especially recommended for vacuum impregnation. They provide excellent adhesion to most materials and have the lowest shrinkage of all cold mounting resins. Curing time is relatively long.

- Very good adhesion

- No shrinkage

- Excellent edge retention

- Low vapor pressure

- Transparency

- Low viscosity

- Long curing time

| |

Edge retention / general usage |

Speed optimized |

| Resin name |

EpoFix

|

SpeciFix

|

CaldoFix-2

|

ProntoFix standard

|

ProntoFix accelerated

|

| Application |

Vacuum & low temperature

Very low shrinkage and ideal for vacuum impregnation of pores and cracks. Ideal for heat sensitive specimens & cover all materials.

|

Extreme adhesion

Very clear mounts that cures relatively fast. Cures in oven or Drybox, while maintaining low shrinkage.

|

All-round vacuum

Short curing time and low viscosity for optimal impregnation. Hardest Struers epoxy mount available.

|

Fast without oven

Speed optimized epoxy resin. Excellent adhesion and superior penetration of cracks & pores when using vacuum impregnation.

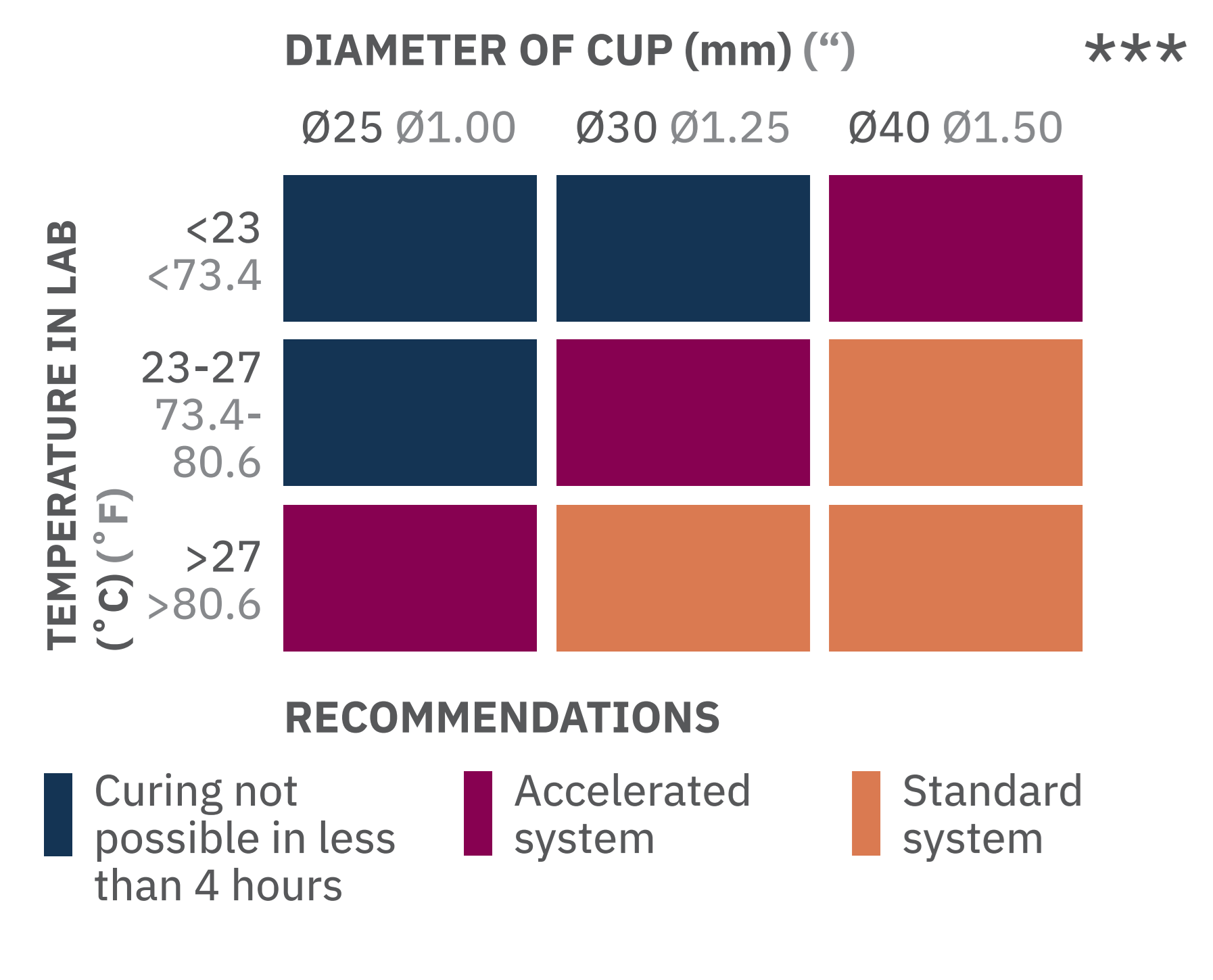

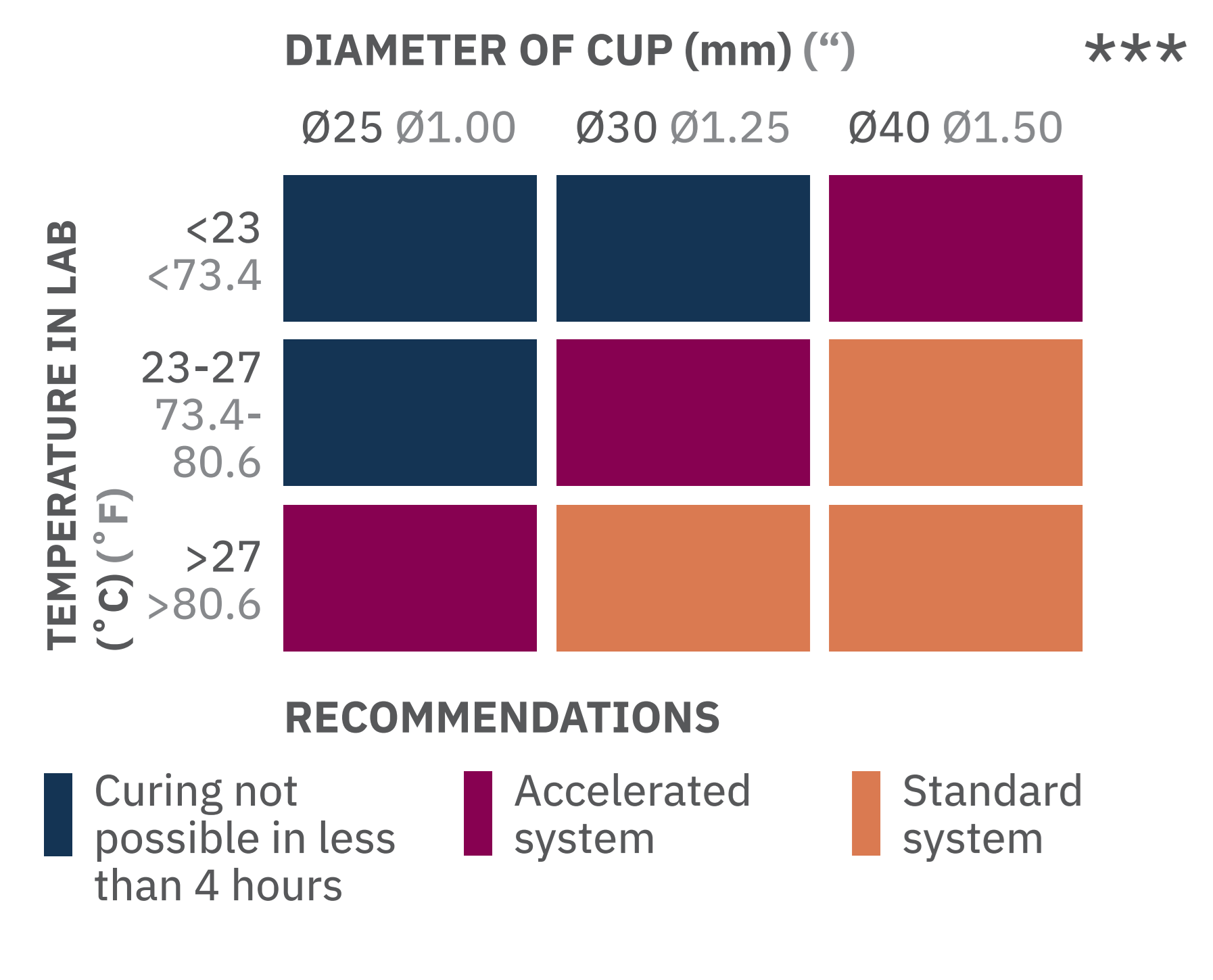

Use of standard vs. accelerated version depends on mounting cup diameter and lab temperature - see table:

|

| Shrinkage level |

Very low |

Very low |

Very low |

Very low |

| Edge retention |

Good |

Good |

Good |

Good |

| Removal rate |

High |

High |

High |

High |

| Mount hardness |

78 Shore D |

82 Shore D |

85 Shore D |

83 Shore D |

| Curing time |

12 hours* |

3½ hours*

(oven at 50 °C / 122 °F) |

90 min*

(oven at 75 °C / 167 °F) |

90 min** |

90 min*** |

| Peak temperature |

115 °C / 239 °F |

90 °C / 194 °F |

75 °C / 167 °F |

100 °C / 212 °F |

138°C / 280 °F |

| Viscosity |

Low |

Low |

Low |

Very low |

* 30 mm dia. mount without specimen at 21 °C / 70 °F.

** 40 mm mount, 10% specimen volume, 25 °C / 73 °F ambient temperature.

*** 30 mm mount, 10% specimen volume, 25 °C / 73 °F ambient temperature.

You can see a full overview in our consumables selection guide