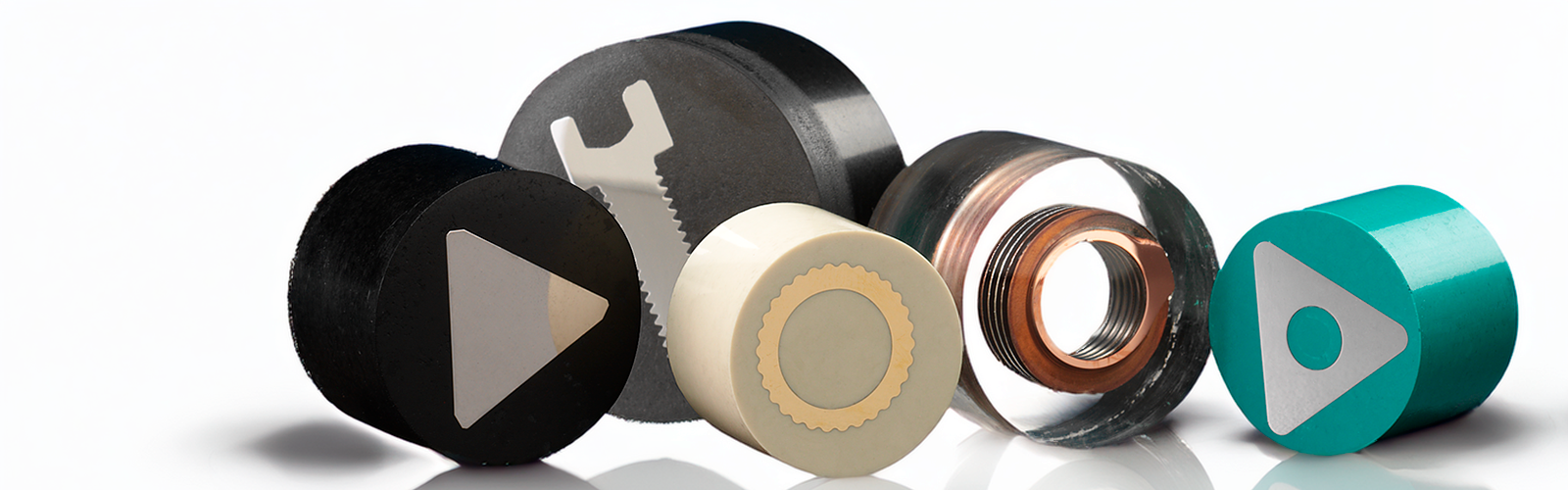

What resin is best for your hot mounting process?

Whether you need high edge retention, rapid mounting, or cost-effectiveness in your hot mounting process, we have got you covered. Our hot mounting resins have been carefully developed to cover any application need.

If you experience gaps around the sample edge after hot mounting, the sample will need to be reworked, adding time and cost to your metallographic process. Our hot mounting resins have been developed to ensure minimal shrinkage and high edge retention – to reduce the need for rework and lower your costs.

| |

Special applications |

Edge retention / general usage |

| Resin name |

ClaroFast

|

CitoFast

|

ConduFast

|

PolyFast

|

DuroFast

|

LevoFast

|

PuriFast

|

MultiFast

|

| Application |

Transparence

Crystal clear mounts good for specimens with pores, voids or empty spaces. Can be used in a mixed mount as an insulator for electrolytical preparation or as a backfill for labelling.

|

Fast

Fastest hot mounting resin on the market. Best suited for soft materials or as "backing" for other resins when speed is of essence.

|

Conductive

Conductive resin relevant when electrolytical polishing and etching is used.

|

SEM analysis

Carbon filler enables SEM examination & offers very low shrinkage + high removal rate.

|

Edge retention

Superior edge-retention for hard & medium hard materials with very low risk of gaps.

|

Edge retention

Excellent edge-retention for medium hard & soft materials with very low risk of gaps.

|

Dust-free

No health hazards & dust free. Recommended for soft to medium hard materials.

|

Routine

Bakelite type resin for routine examination of soft to medium hard materials, or as backfill. Three colors available.

|

| Shrinkage level |

Low |

Low |

Low |

Very low |

Very low |

Very low |

Medium |

Medium |

| Edge retention |

Fair |

Fair |

Fair |

Good |

Excellent |

Excellent |

Fair |

Good |

| Removal rate |

High |

High |

High |

High |

Low |

High |

High |

Medium |

| Mount hardness |

81 Shore D |

86 Shore D |

76 Shore D |

87 Shore D |

86 Shore D |

88 Shore D |

62 Shore D |

87 Shore D |

| Mounting time* (incl. heat-up) |

10.5 min |

3.5 min |

5 min |

5 min |

5.5 min |

5.5 min |

5 min |

5 min |

* 30 mm dia. mount with a 45 % carbon steel specimen (20 vol %)

You can also download our complete consumables selection guide