Hot mounting

Hot mounting is your go-to method when speed and reproducibility are crucial for preparing metallographic samples. This technique allows for quick embedding of samples in a resin, providing uniform mounts with minimum risk of mount material shrinkage. Struers hot mounting solution offers all the elements required for excellent hot mounting outcome:- Hot mounting presses for higher speed, reliability, and repeatability

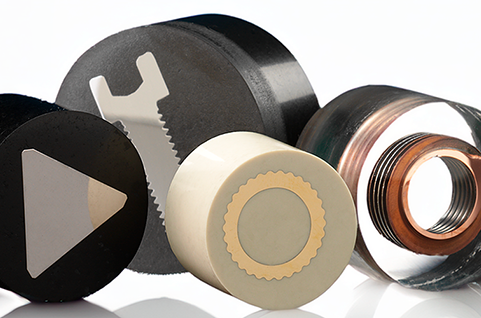

- Hot mounting resins for excellent edge retention with any material

- Hot mounting accessories to support any mounting process